Overview

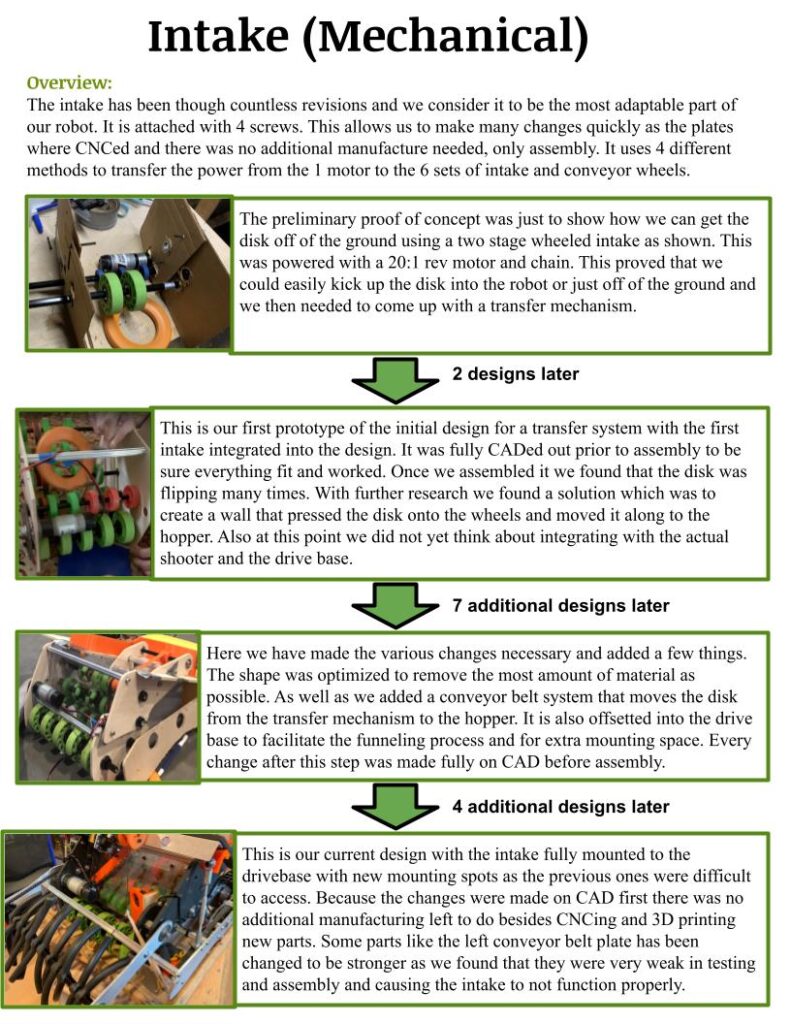

First Tech Challenge (FTC), is one of the organizations in which I participated for robotics competitions. When I began working on this robot, it marked my second year on the team. I aspired to become more deeply engaged in the actual construction and design of the robot, in contrast to the previous year when I mainly observed other team members and acquired fundamental concepts.

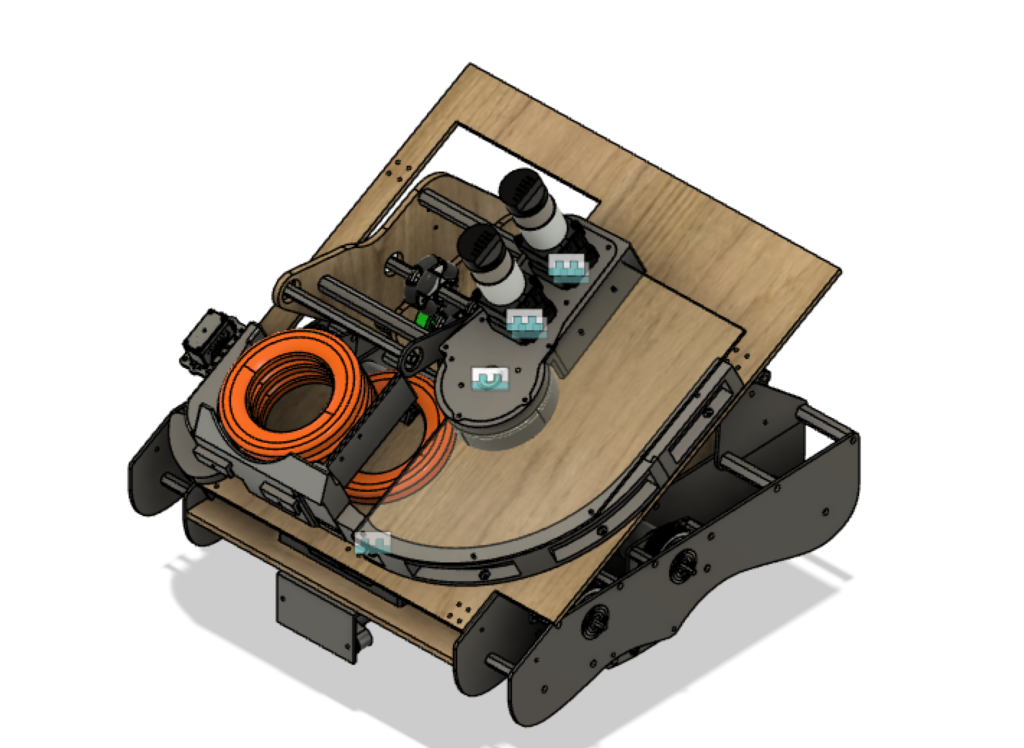

The challenge entailed creating a robot capable of picking up foam rings and launching them into various elevated goals.

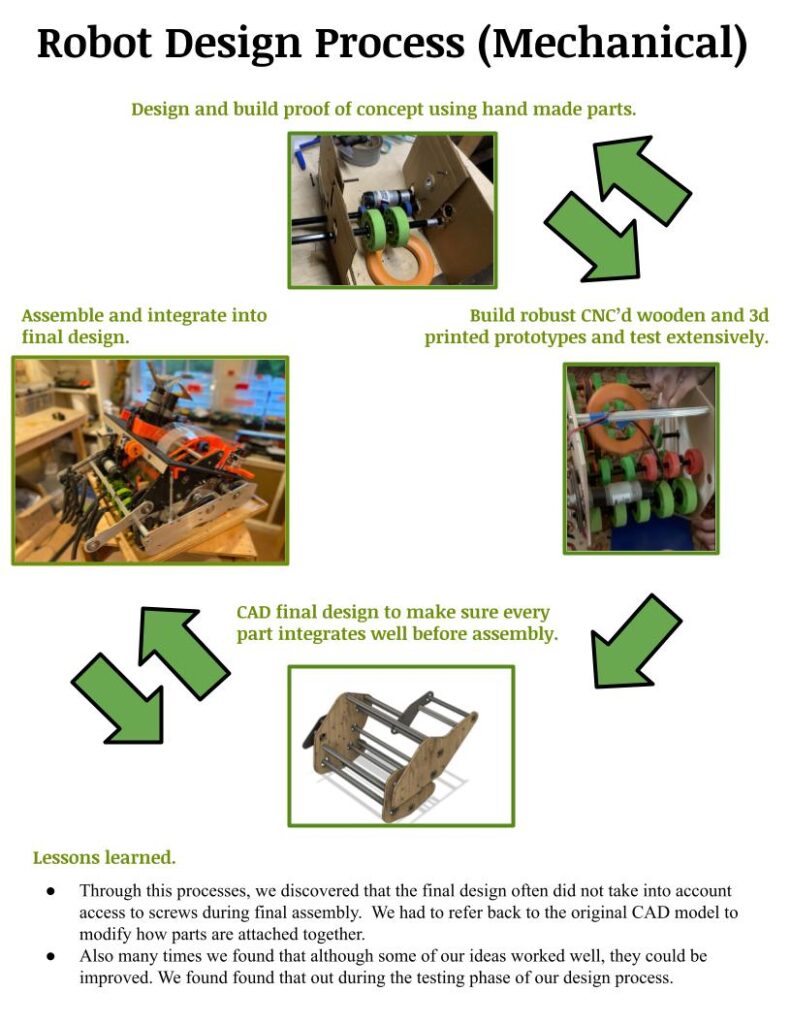

Process

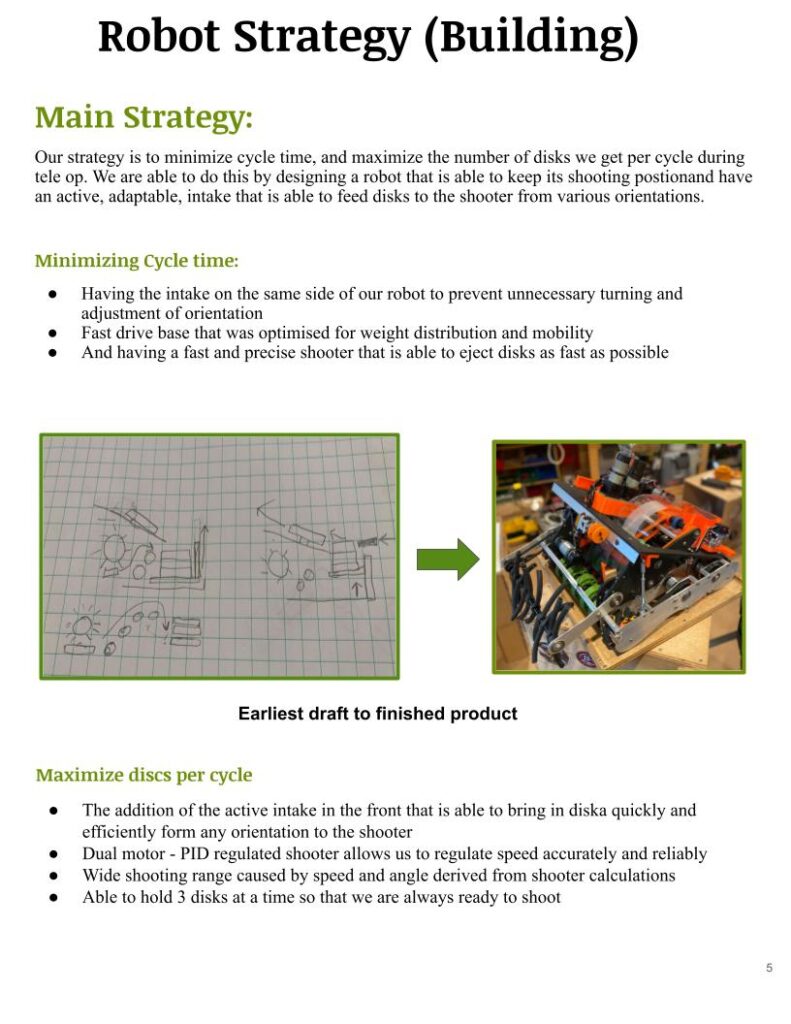

Brainstorming

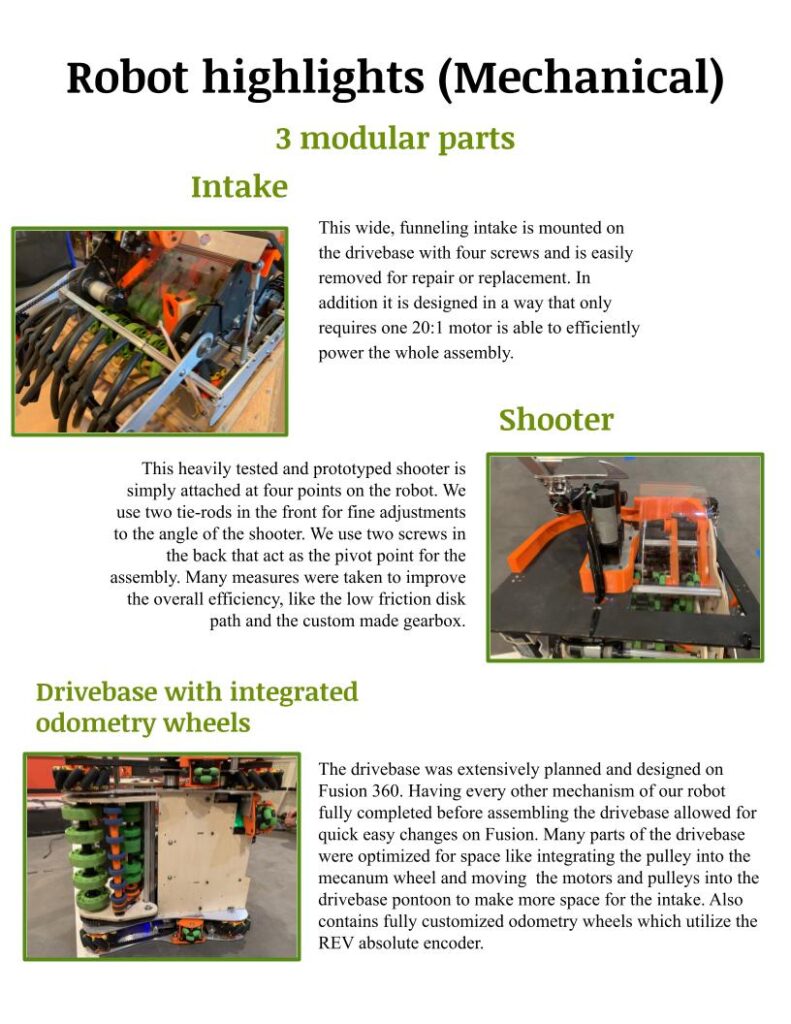

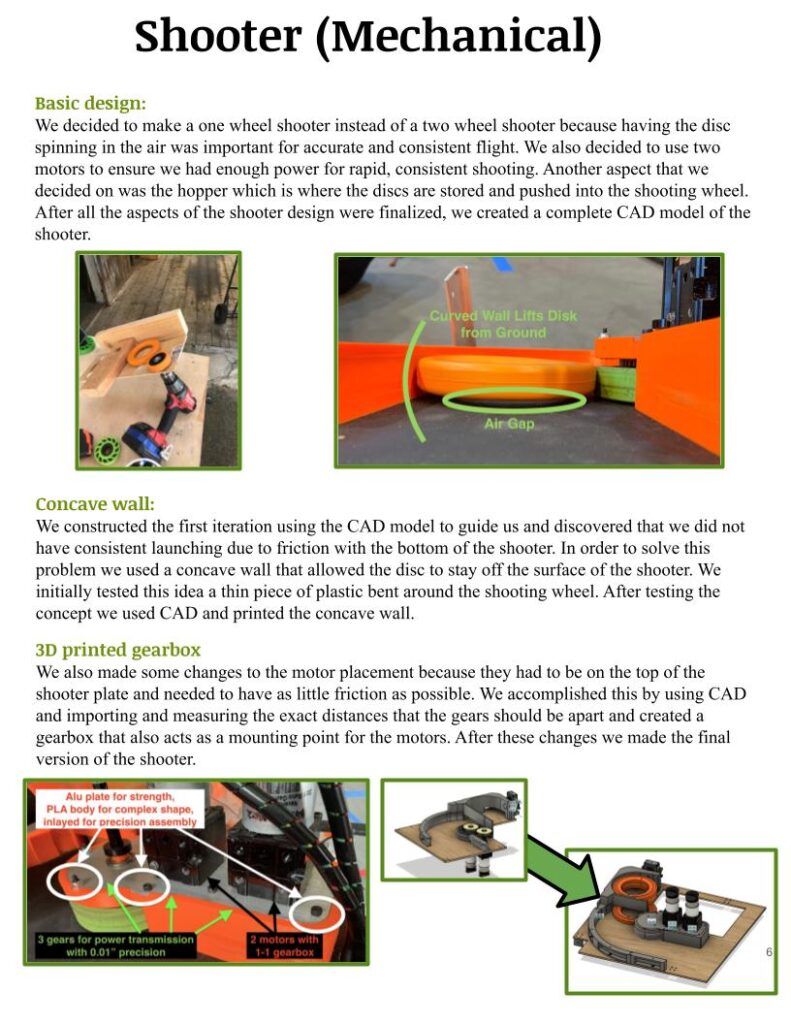

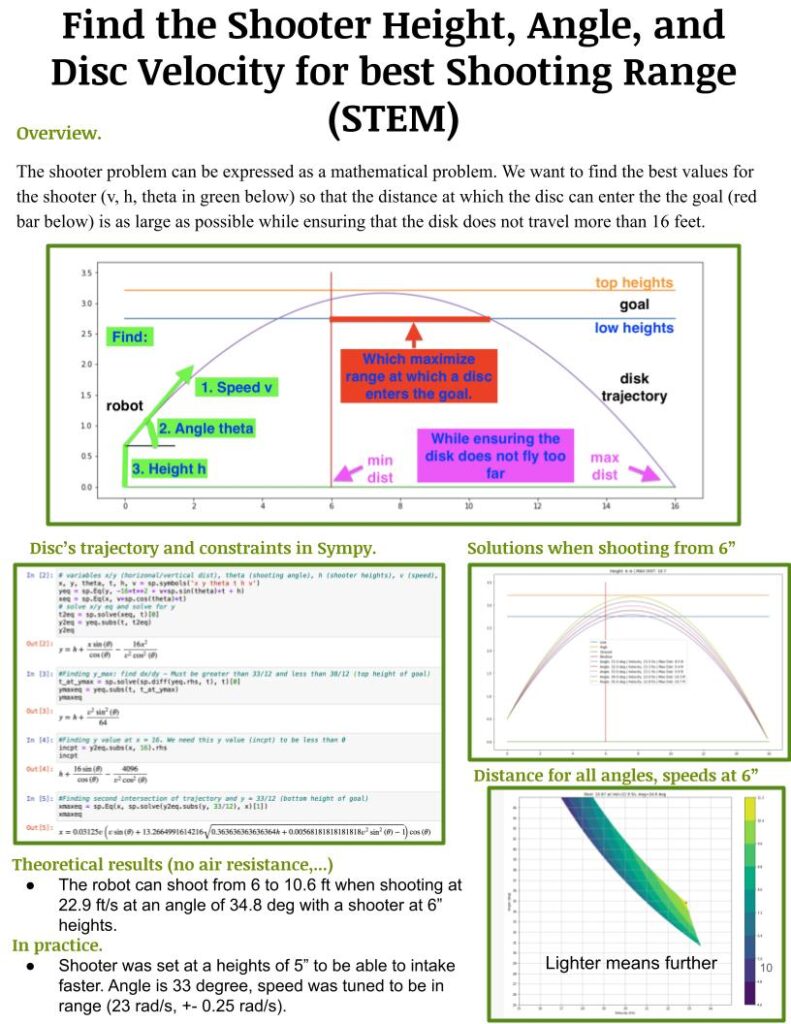

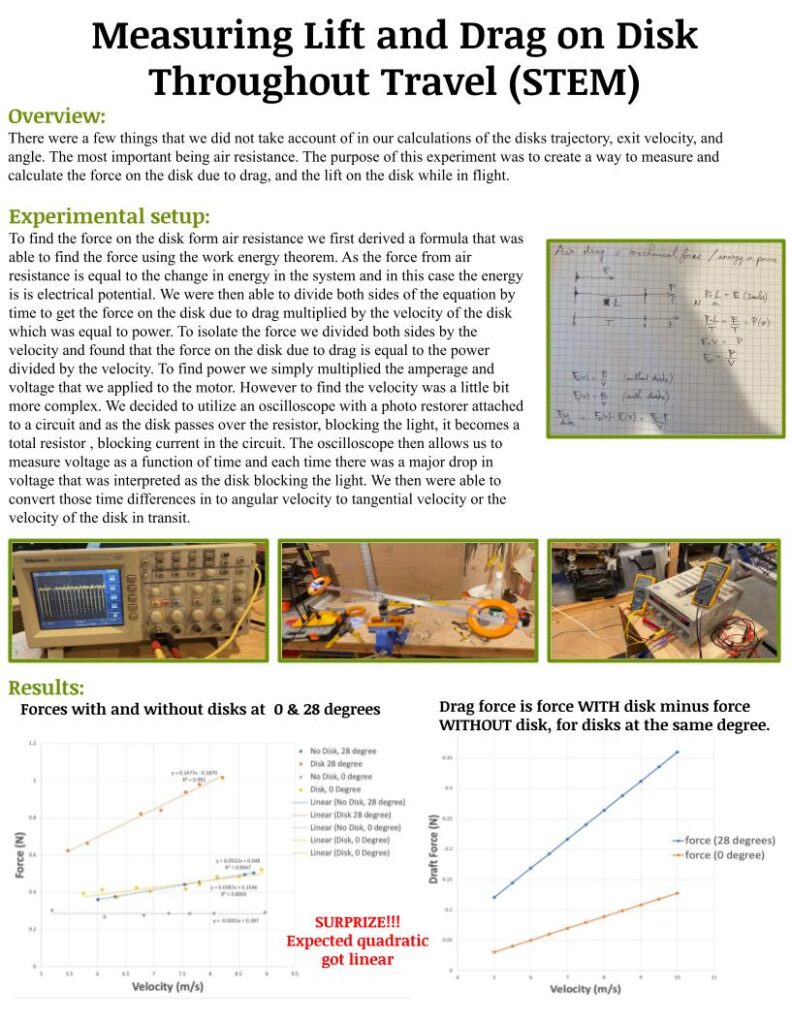

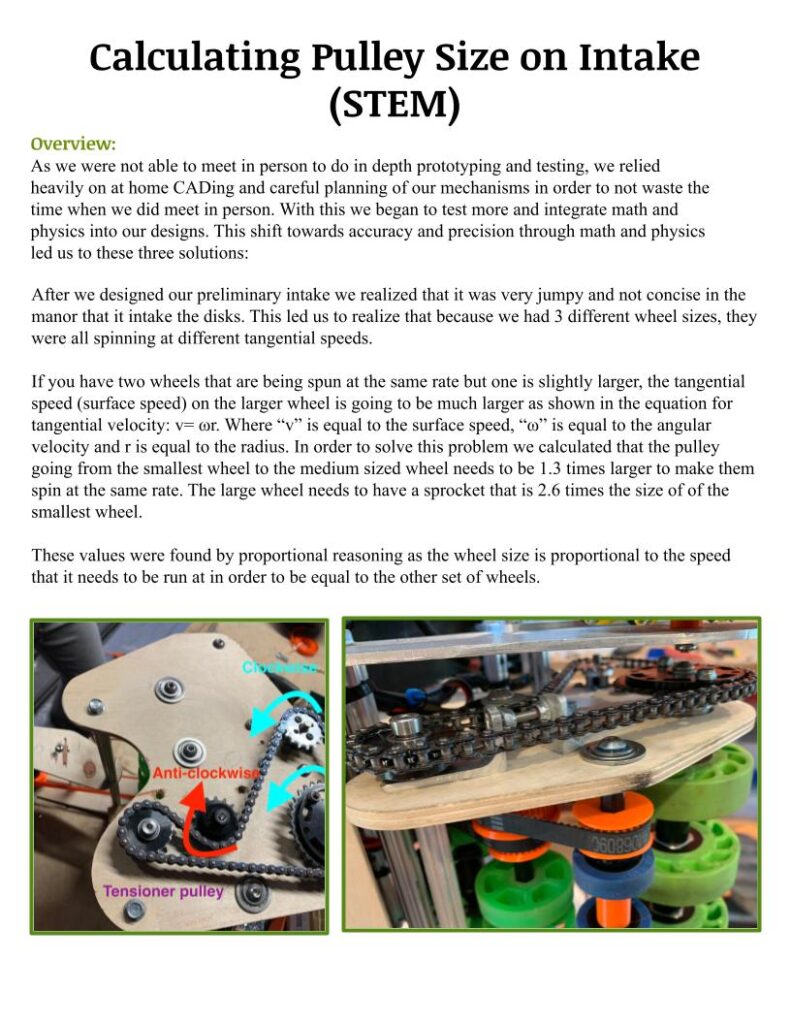

I primarily concentrated on designing and creating the shooter mechanism while also providing assistance in other aspects of the robot. My initial approach to building the shooter involved testing the required speed and angle to optimize its effectiveness. I achieved this by constructing a basic prototype using a drill fitted with an attached flywheel. As a team, we collectively decided that a flywheel would offer the best solution for achieving a rapid and consistent firing mechanism.

Flywheel and Gearbox

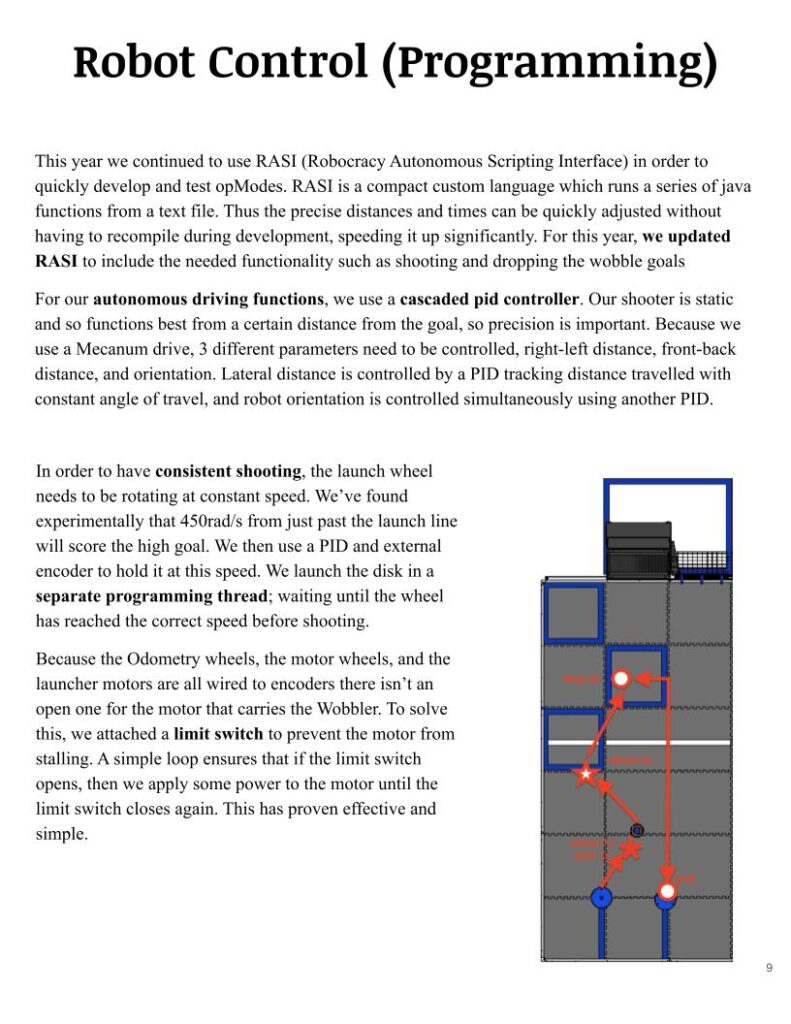

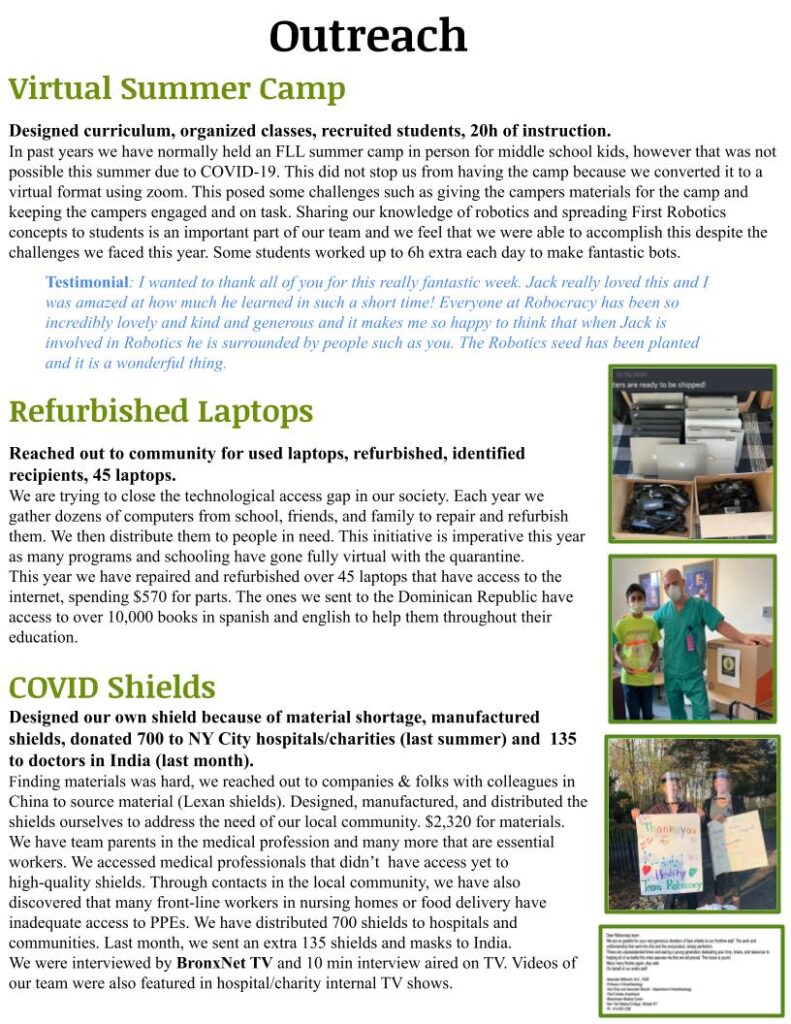

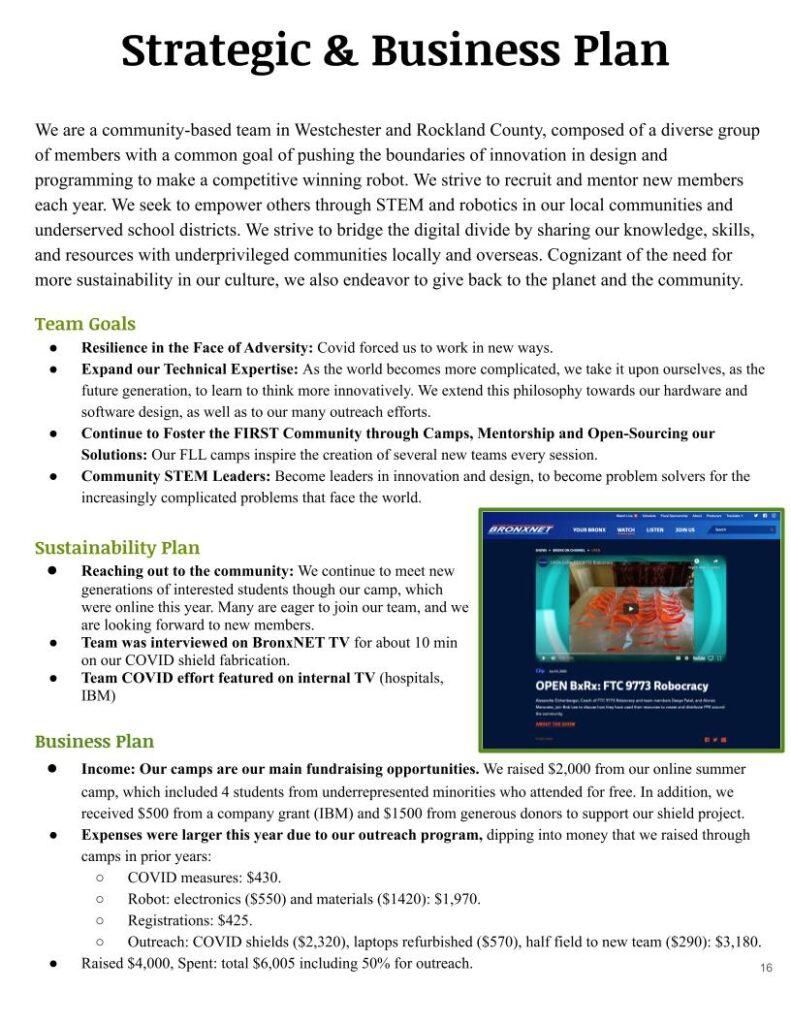

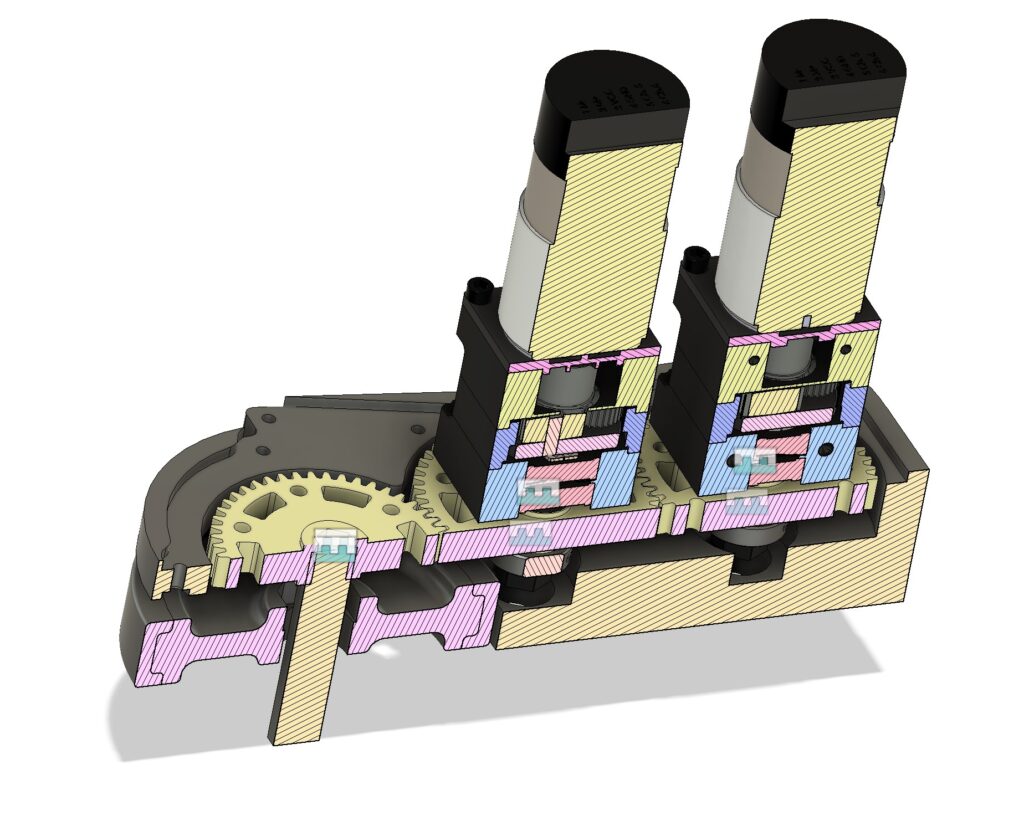

Upon finishing all the testing and calculations to determine the optimal measurements and constraints for the shooter, I began the construction of a CAD model encompassing the shooter and its components. Our objective was to ensure that the shooter possessed sufficient torque, preventing the wheel from experiencing significant slowdown following disc firing. Consequently, we settled on utilizing two motors to drive the single flywheel. The process of crafting this gearbox involving dual motors imparted many insights into gear tolerances and broader structural design principles.

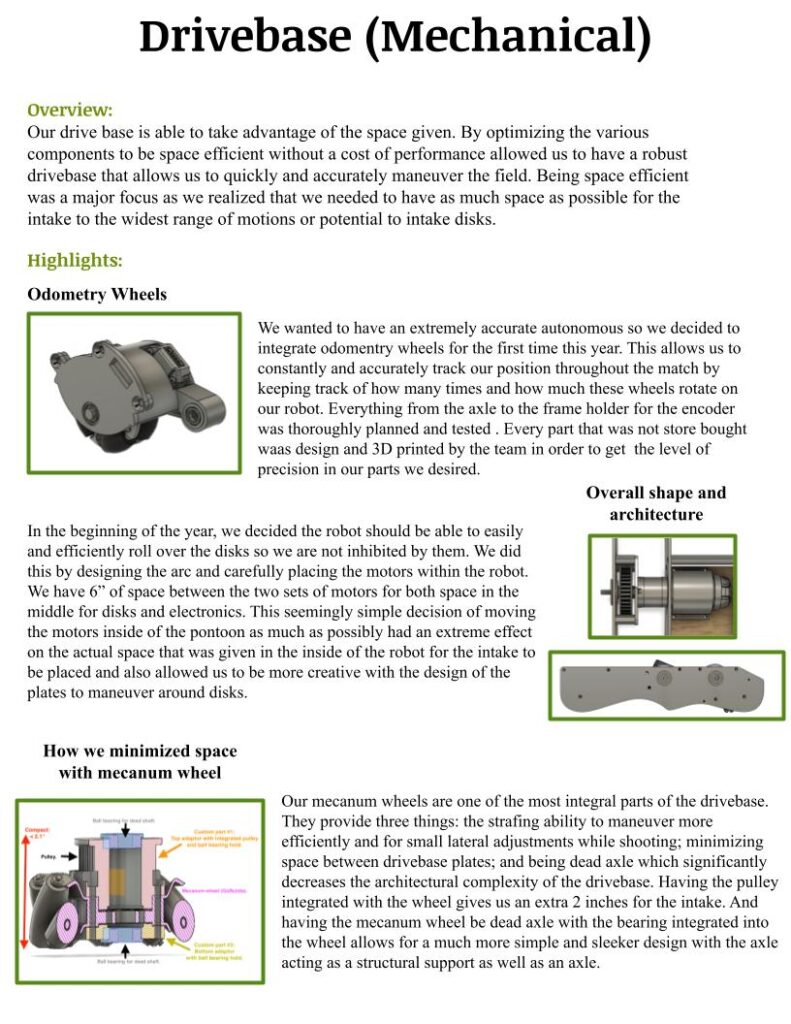

Curved Wall

After completing the dual-motor gearbox, we initiated the process of working on the curved wall along which the disc would be accelerated. I collaborated closely with Aman to fashion this piece, which was simple in nature yet held a certain complexity. The intricacy stemmed from the requirement that the distance between this wall and the flywheel needed to be precisely calibrated. Consequently, we designed it to be highly adjustable, enabling us to conduct testing. Once we determined the optimal positioning, we could secure it firmly in that configuration.

Additionally, we incorporated a curved inner wall to elevate the disc above the floor of the shooter, thereby eliminating any friction. To accommodate the size of the part, we divided it into multiple sections and 3D printed each section before assembling them together.

Engagement Mechanism

The concluding element of the shooter was the engagement mechanism, consisting of a servo arm that pushed a single disc from the intake into the shooter for firing.

Engineering Portfolio

This series of slides presents pictures and even more details about the process the team undertook to create the robot. Below is a preview of the Engineering portfolio. Please use the button to access the full version.