Overview

During my second semester at Northeastern University, I enrolled in an engineering class titled “Cornerstone of Engineering 1 and 2.” The final project’s scope was wide, yet it had a particular emphasis on sustainability. Consequently, my group and I opted to develop a light-up dog leash that harnessed energy from the dog’s pulling on the leash. This innovative device aimed to promote sustainability, enhance pet safety, and provide user convenience, as it would eliminate the need for battery replacements.

Brainstorming

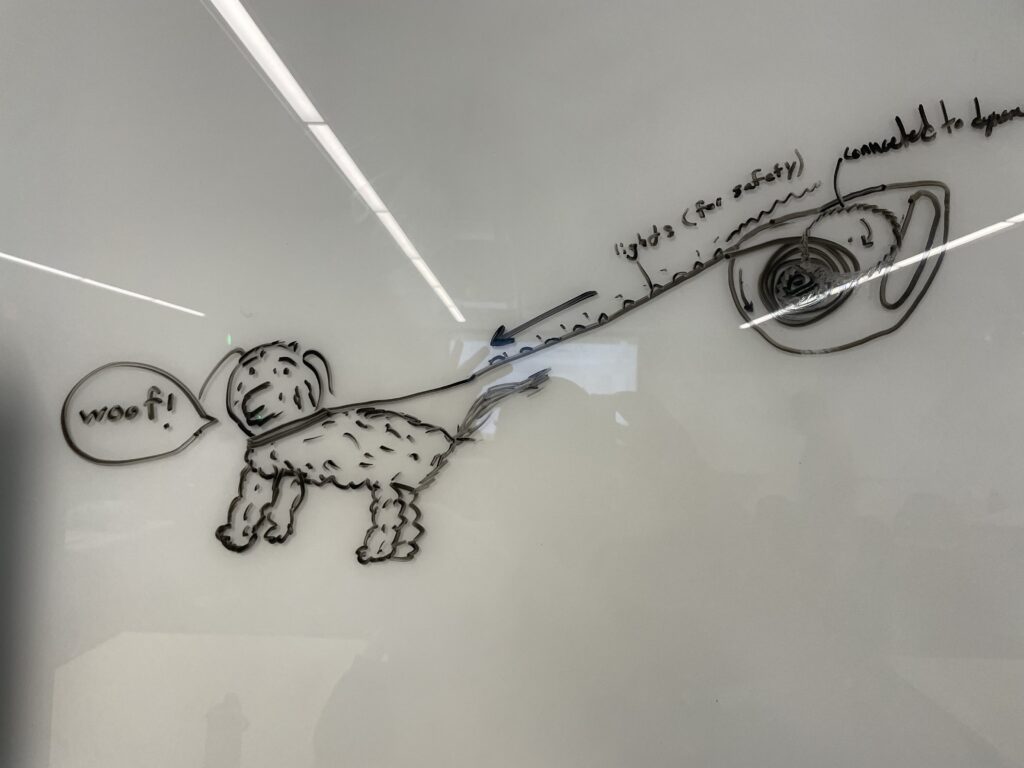

The conclusions that the team arrived at during brainstorming were that we wanted to utilize a dynamo generator connected to a retractable dog leash to provide power to an LED light strip that would be affixed to the dog’s collar.

Design

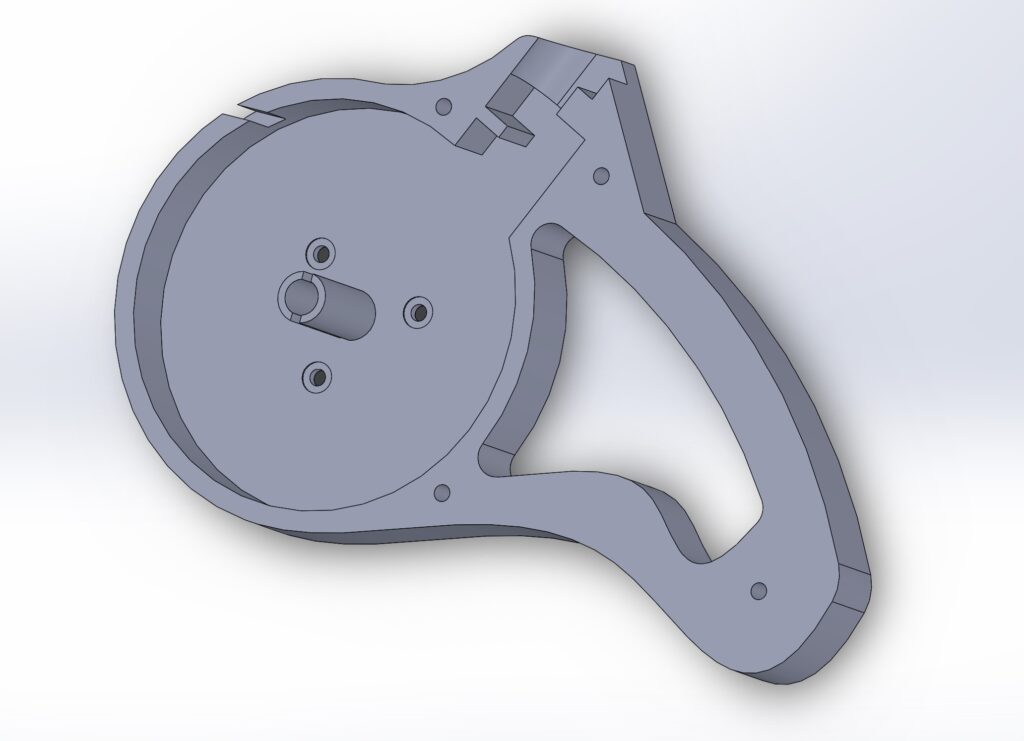

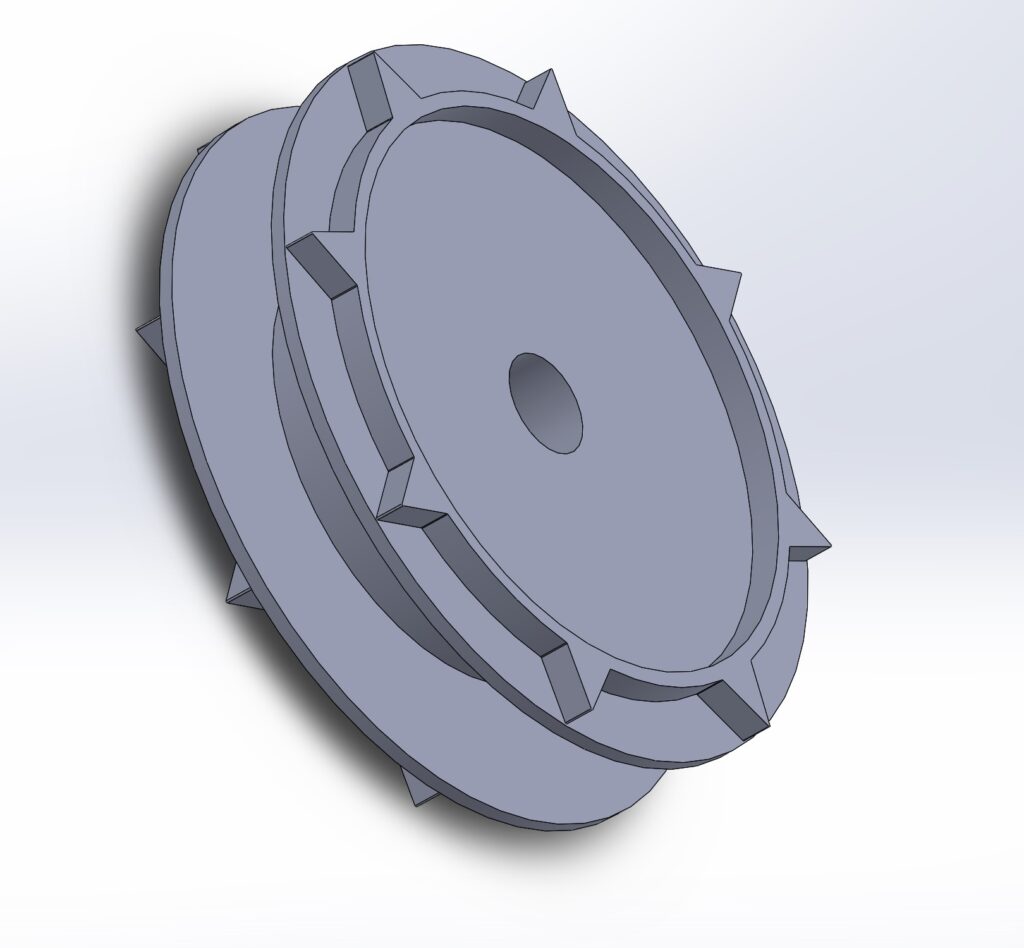

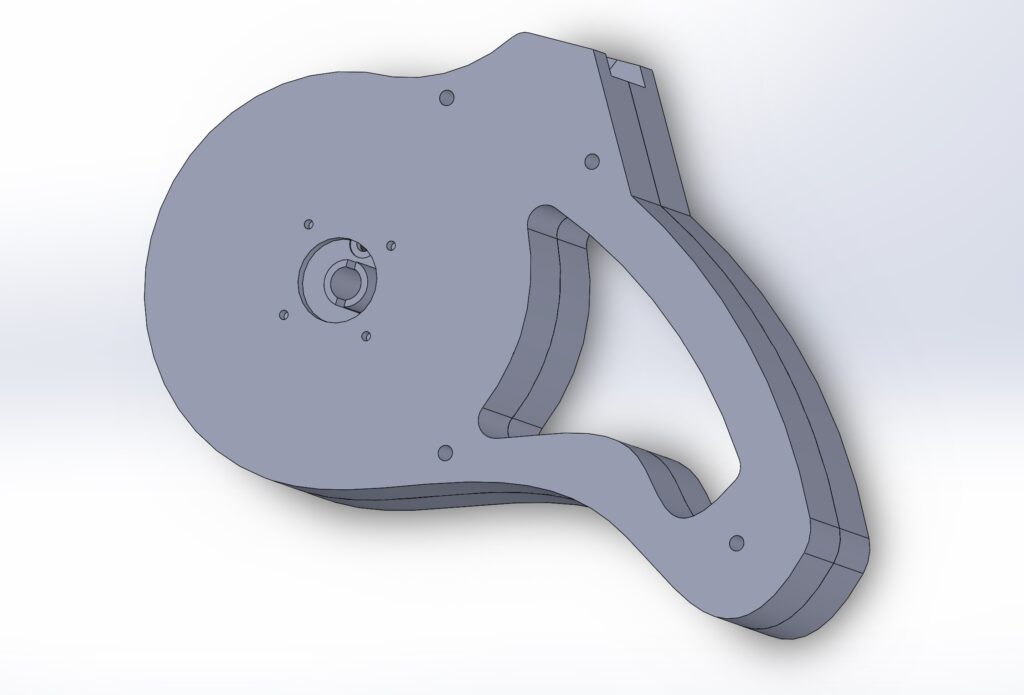

The team acquired a retractable dog leash and dismantled it to comprehend the inner workings of the device’s mechanisms. Subsequently, I started a CAD model influenced by the reverse-engineered leash, incorporating alterations to accommodate the additional components we intended to integrate. This model was crafted using measurements derived from the various components we had collected, including a dynamo generator and a wire rotator cable.

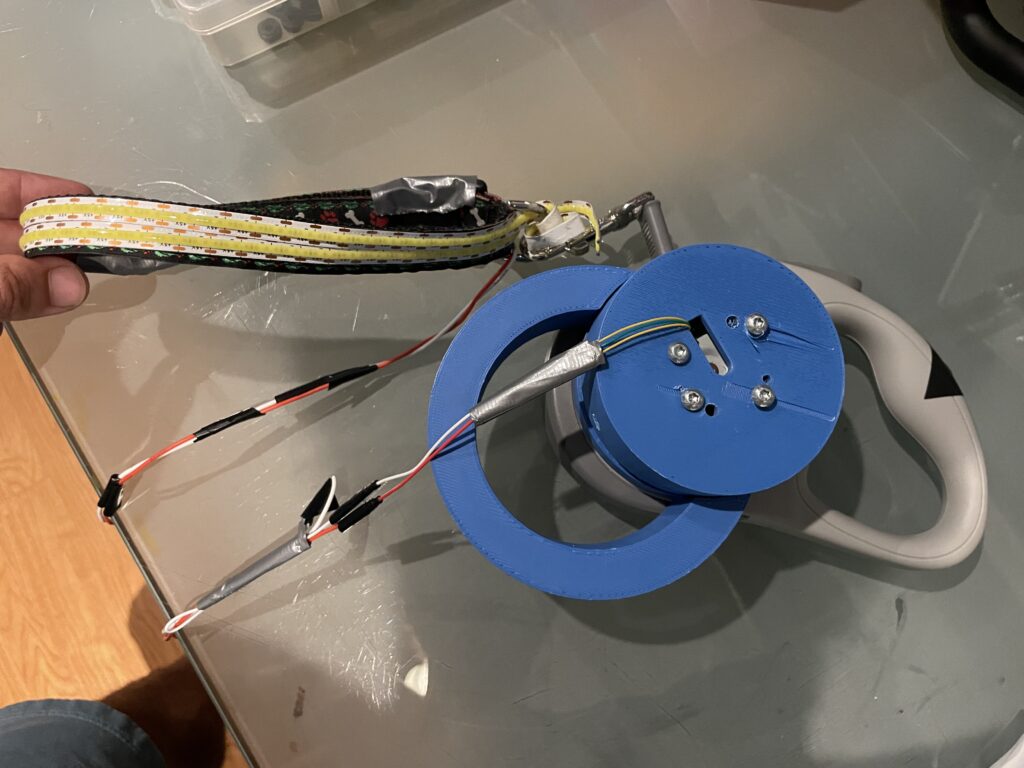

Construction

The construction process for this project mainly involved creating larger 3D prints and soldering wires and electronic components. The primary challenge we encountered was related to the torsion spring inside the retractable leash, as it proved difficult to safely remove and contain. In order to address this problem, we procured an additional leash and left it mostly intact to avoid disturbing the spring. Instead, on the final iteration we affixed the electronics onto the existing leash.